Building & Construction

Advanced Plastics for Modern Building Projects

Plastic materials have become indispensable in the building and construction industry due to their exceptional properties. First and foremost, their lightweight and durable nature is a game-changer. With outstanding strength-to-weight ratios, plastics excel in applications where weight is a concern. They ensure that structures and components can withstand the harshest environmental conditions, including extreme weather, without compromising on performance. This durability not only extends the lifespan of constructions but also reduces maintenance and replacement costs, making plastics an attractive choice for various projects.

Moreover, the cost-effectiveness of utilizing plastics in construction is a key factor driving their widespread adoption. Compared to traditional materials like metal or concrete, plastics offer significant cost savings. These lower costs open up new possibilities for ambitious and creative architectural designs that were once constrained by budget limitations. Architects and engineers can now explore innovative structures that combine aesthetic appeal with functionality, all while staying within budgetary constraints.

Plastics' versatility is another critical aspect of their importance in the industry. Their diverse range of properties can be tailored to meet specific construction requirements. From rigid to flexible, transparent to opaque, and flame-resistant to insulating, plastics can be engineered to adapt to various applications. This adaptability allows for the creation of customized solutions that address the unique challenges posed by different construction projects.

Furthermore, as the world moves towards sustainable practices, plastics play a pivotal role in the green revolution within the construction industry. Many plastic materials are recyclable and can be reused in various applications, significantly reducing their overall environmental impact. Their contribution to sustainable construction practices has led to the development of eco-friendly buildings with reduced carbon footprints.

In addition to being sustainable, plastic materials also enhance energy efficiency in buildings. Their excellent insulation properties help to reduce heat transfer and overall energy consumption, resulting in lower heating and cooling costs. Energy-efficient windows, doors, and insulation systems made from plastics contribute to environmentally conscious construction practices, making buildings more environmentally friendly and cost-effective in the long run.

The natural resistance of plastics to corrosion further solidifies their importance in construction. Unlike traditional materials like metal, plastics are not prone to rust or degradation when exposed to moisture and chemicals. This corrosion resistance makes them an ideal choice for outdoor and underwater applications, where durability and longevity are essential considerations. Beyond their technical advantages, plastics enhance the comfort and safety of living and working spaces. They provide effective acoustic and thermal insulation, creating a serene and pleasant environment even in crowded urban settings with high noise levels and temperature fluctuations. Additionally, plastics contribute to improved safety in construction by offering features like shatter-resistant glazing materials for windows, minimizing potential hazards during natural disasters or accidental impacts.

Finally, plastic materials empower architects and engineers with design flexibility, unlocking a realm of creativity. Their ability to be molded into various shapes, combined with their aesthetic appeal, enables the realization of cutting-edge designs that capture attention and elevate the art of architecture. This creative freedom allows construction professionals to push the boundaries of innovation, resulting in striking and functional structures that shape the urban landscape. The importance of plastics in the building and construction industry cannot be overstated. Their lightweight and durable properties, cost-effectiveness, versatility, sustainability, energy efficiency, corrosion resistance, acoustic and thermal insulation, design flexibility, and safety enhancements make them indispensable for modern construction practices. As the industry continues to evolve, plastics will undoubtedly play a leading role in shaping sustainable, aesthetically pleasing, and innovative structures that meet the demands of a dynamic and eco-conscious world.

Business & Construction Applications

- Commercial, institutional and residential greenhouses

- Entryway canopies

- Bus shelters, specialty enclosures

- CarportsSloped and curved glazing

- Skylights

- Security windows, hurricane glazing and shutters

- Sound barriers

- Interior partitions, room dividers

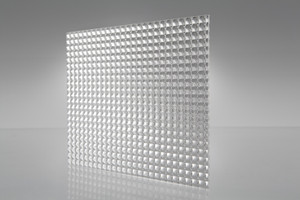

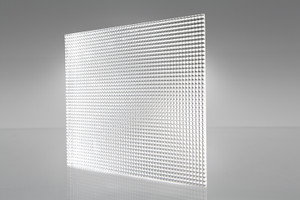

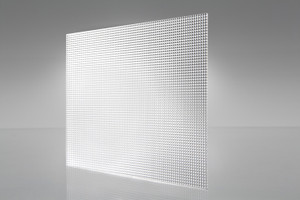

- Lighting lenses, tubes and louvers

- Mirrors

- Furniture, benches and tables

- Corner guards and run rails

- Barrier, protective and reflective films

- Caulking and sealants

- Piping

- Wiring jacketing

- Bearing pads

Advantages May Include

- Lightweight for faster and safer installation

- High impact strength

- Hailstone and hurricane resistant

- Lighter than glass

- Lower f reight costs than heavier materials

- High strength-to-weight ratio

- Easy to fabricate, including on-site fabrication

- Building code approved

- Fire resistant; does not give off toxic gasses

- UV resistant

- Transparent/high light transmission

- Wide range of color or tint options

- Easy to decorate

- Energy efficient; excellent thermal insulation properties

Sustainable, can be recycled - Chemical resistance

Materials

- Acrylic (PMMA)

- Chlorinated Polyvinyl Chloride (CPVC)

- Ethylene Tetrafluoroethylene (ETFE)

- Fiber-Reinforced Plastic (FRP)

- Polycarbonate (PC), including Multiwall

- Polycarbonate

- Polyethylene Terephthalate (PETG)

- Polyvinyl Chloride (PVC)

- PVC/Acrylic Alloy (PMMA)

- Polyolefin Alloy (PO)

- Polypropylene (PP)

- Polystyrene (PS)

- Recycled Plastic Lumber

- Polyethylene (PE)

- Polyvinyl Flouride (PVC)

- Polytetrafluroethylene (PTFE)

- Perfluoroalkoxy (PFA)

- Silicone (SI)