X-Ray Detectable

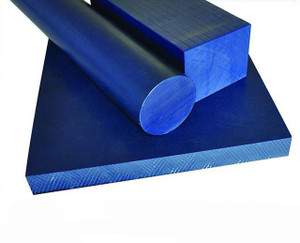

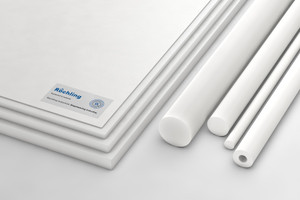

X-ray Detectable Plastics are specially formulated materials designed to be visible under X-ray imaging systems. These innovative plastics are crucial in environments where non-detectability of foreign objects could lead to severe health risks, such as in medical applications and food processing industries. By incorporating certain additives or fillers, these plastics become detectable by X-ray machines, enhancing safety protocols and reducing the risk of contamination.

Key Characteristics and Advantages:

Enhanced Detectability: The primary benefit of X-ray detectable plastics is their ability to be easily identified by X-ray imaging systems. This feature is vital for detecting fragments or particles that may inadvertently contaminate products during manufacturing or usage.

Medical Grade Safety: In the medical field, these plastics are used to manufacture components that are safe for use in surgical instruments, medical devices, and other applications where non-detectable items pose a significant risk to patient safety.

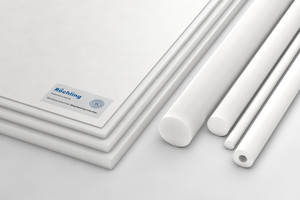

Versatility: These materials can be engineered to fit a wide range of applications, from custom tools and machine parts to packaging and handling equipment. Their adaptability makes them an ideal choice for various industries requiring high levels of safety and contamination control.

Food Industry Compliance: X-ray detectable plastics meet stringent food safety standards, making them suitable for use in food processing equipment. They help in preventing contamination by ensuring that any plastic fragments can be detected and removed before products reach consumers.

Durability and Performance: Despite their specialized composition, X-ray detectable plastics retain the physical properties of standard engineering plastics, offering strength, durability, and resistance to chemicals and temperatures.