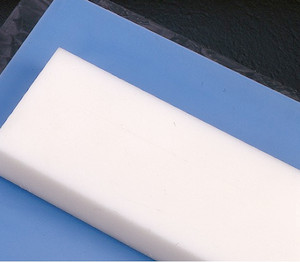

LDPE

Versatile and Durable Solutions for Diverse Industries

Discover the world of Low-Density Polyethylene (LDPE), a highly versatile and widely used thermoplastic known for its unique blend of flexibility, durability, and chemical resistance. At Port Plastics, our LDPE offerings are tailored to meet the diverse needs of multiple industries, from packaging and consumer goods to agricultural and automotive applications. This lightweight yet strong material stands out for its ease of processing and customization, allowing for a vast range of products including films, containers, and plastic parts. Its low-temperature impact resistance and excellent electrical properties make LDPE an ideal choice for a variety of challenging environments. Embrace the efficiency and reliability of LDPE in your next project with Port Plastics, where quality meets innovation.

Applications of Low-Density Polyethylene (LDPE)

- Packaging Solutions: LDPE is extensively used in creating flexible packaging materials. This includes bags for dry cleaning, newspapers, bread, frozen foods, and garbage. Its moisture-resistant property makes it ideal for food storage and packaging.

- Consumer Goods: Durable and safe, LDPE is the material of choice for manufacturing household items like squeezable bottles, toys, and containers. Its flexibility and resistance to chemicals enhance product longevity and safety.

- Medical and Pharmaceutical Uses: Due to its non-reactive nature, LDPE is perfect for medical equipment and pharmaceutical packaging. It's commonly used in manufacturing surgical products and laboratory containers.

- Agricultural Applications: In the agricultural sector, LDPE's durability against environmental factors is leveraged for water storage tanks, silos, and agricultural films.

- \Construction and Building Materials: LDPE is utilized in the construction industry for its insulation properties in wires and cables. It's also a key component in some waterproofing materials.

Product Features of LDPE

- Flexibility and Strength: Despite being one of the softer and more flexible plastics, LDPE maintains a significant level of strength and toughness.

- Moisture Resistance: LDPE is inherently moisture-resistant, making it an excellent barrier against liquids, which is crucial for packaging and storage solutions.

- Chemical Resistance: It offers resistance to acids, bases, vegetable oils, and alcohols, making it suitable for a wide range of applications.

- Low-Temperature Resistance: LDPE maintains its properties at low temperatures, making it ideal for applications in cold environments.

- Electrical Insulating Properties: Due to its high dielectric strength, LDPE is commonly used in the production of electrical components and insulators.

- Ease of Processing: LDPE can be easily processed through most plastic molding methods, which includes injection molding, extrusion, and blow molding.

- Recyclability: LDPE is recyclable, which supports environmental sustainability efforts and circular economy principles in manufacturing.