Metal Detectable

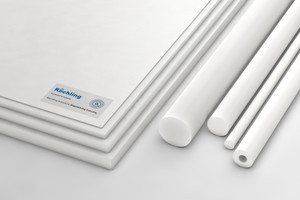

Metal Detectable Plastics are specifically engineered materials designed to enhance safety and compliance within critical environments such as food processing, pharmaceutical manufacturing, and any application where contamination prevention is paramount. These innovative plastics incorporate metallic particles, enabling them to be detected by metal detection and X-ray equipment commonly used in quality control processes.

Key Features and Benefits:

Detectability: Infused with special additives, these plastics can be identified by metal detectors and X-ray systems, significantly reducing the risk of contamination by foreign objects. This feature is critical in preventing costly recalls and ensuring consumer safety in food and pharmaceutical products.

Durability and Usability: Despite their specialized composition, metal detectable plastics maintain the high strength, durability, and ease of use characteristic of traditional plastics. They are designed to withstand the rigorous conditions of manufacturing environments, including exposure to chemicals, high temperatures, and repeated cleaning processes.

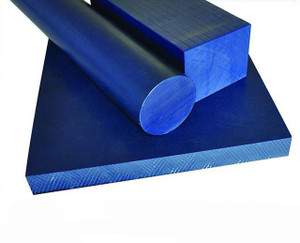

Versatility: Available in a variety of forms, including sheets, rods, and custom shapes, these materials can be used to manufacture a wide range of products. Common applications include conveyor belt scrapers, machine parts, and custom tools that are at risk of breaking and contaminating the product line.

Compliance and Safety: Utilizing metal detectable plastics in production lines helps businesses comply with stringent industry regulations and standards for product safety. Their use demonstrates a commitment to maintaining the highest levels of hygiene and consumer protection.

Cost-Effectiveness: By reducing the risk of product recalls and enhancing the efficiency of detection systems, metal detectable plastics offer a cost-effective solution for improving product safety and quality control processes.