Upstream AUX Components

In the Energy market, the upstream segment is where the Fossil fuels (oil & gas) are extracted, exposing aggressive mixtures of crude oil, water (brine), and gases (CH4, C02, and H2S) but not limited to the additional additives from the topside to recover these fluids, Engineers add acids, corrosive inhibitors, biocides, frac fluids, etc. As a neutral supplier, Port Plastics works closely with their customers and suppliers to source the highest quality of advanced engineered thermoplastics to support HPHT critical and noncritical applications and reduce MTBF while increasing performance to meet the end-user’s goals. Below are a few examples of materials and machined components applied in the upstream segment on land, the offshore platform, and the deep-sea floor.

Brief Listing of Upstream Components

Product: large Diameter Segmented Welded Ring

Material: Peek, PVDF, PTFE, PPS

Applications: O&G, Aerospace, BU rings, turrets, Hi Press Seals, FPSO, Military Equip

Product: Ball Valve seats

Material: Peek, Special PTFE grades

Applications: Special materials to meet the challenges of low emissions allowing the peek to be more flexible.

Product: Wear Pads for FPSO Turrets

Material: PA66

Applications: O&G, applied to protect bearings load shift of tidal flow

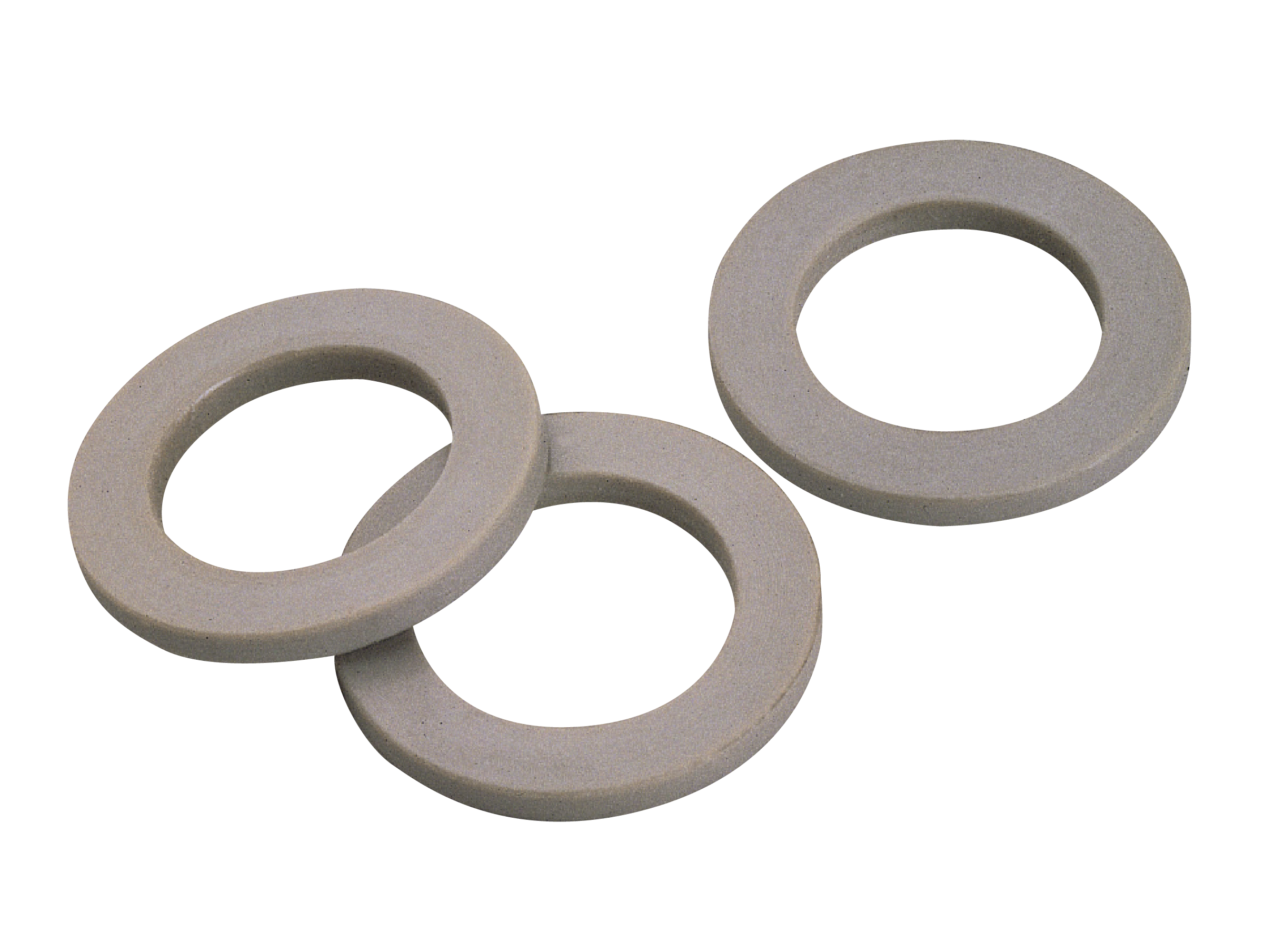

Product: Large Dia. Peek Rings

Material: Peek, filled grades of Peek

Applications: Hi pressure seal, BU rings, spacers, guide rings

Product: ROV & X-tree funnels

Material: Special PET grade

Applications: Used to connect hydraulic, electrical, and gas lines by ROV’s – High strength

Product: Frac balls

Material: Peek, filled grades of Peek, PET, G10

Applications: Hi pressure seal fractured zones for both onshore and offshore in various sizes

Application Zones by Pressure & Temp

- SP/ST = Standard Pressure/Std Temperature

- Temperature= 200 - 350°F

- Pressure= 0- 15 KPSI

- SP/HT = Standard Pressure/High Temperature

- Temperature= 350°F - 450°F

- Pressure= 0- 15 KPSI

- HP/HT = High Pressure/High Temperature

- Temperature= 350°F - 450°F or Higher

- Pressure= 15 KPSI - 30 KPSI

- HP/ST = High Pressure/Std Temperature

- Temperature= 200°F - 450°F or Higher

- Pressure= 15 KPSI - 30 KPSI

Common Materials Used in Auxiliary Components

- UHMW-PE

- PA66

- PPS

- PEEK, PTFE Filled Peek

- Glass Filled

- Carbon Fiber Filled Peek

- Engineered Grades of PTFE

- PI

- PAI

- PBI

What is considered HP/HT ?

In review of the above HPHT chart and looking beyond the Standard Development section, each of the three other sections are challenged to selecting the correct polymer material based on the customers design and operating data for pressure, temperature, corrosive concerns, and regulatory controls which maybe required. Port Plastics as a neutral supplier can solve your material concerns and/or machined component as full technical solution provider.