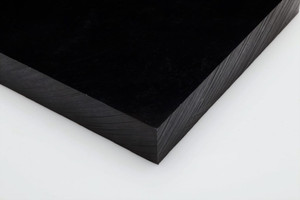

Conductive

Conductive plastics are defined by a surface resistivity in the 102 to 104OMEGA SYMBOL/sq. and have electric current decay rates measured in nanoseconds! Additive technology has to be such that the properties of the product are achieved while the machinability of the plastic is maintained.

The plastic as such also needs to maintain its conductive properties consistently throughout the plastic shape. Conductive plastics are available in a variety of raw resins which can be tailored to the applications thermal and physical property needs. Conductive plastics are also available in a variety of technologies to acheive conductivity such as graphite filled, carbon fiber filled, and CNT or carbon nanot tube filled. All of these variations have a profound effect on the performance of the finished thermoplastic.