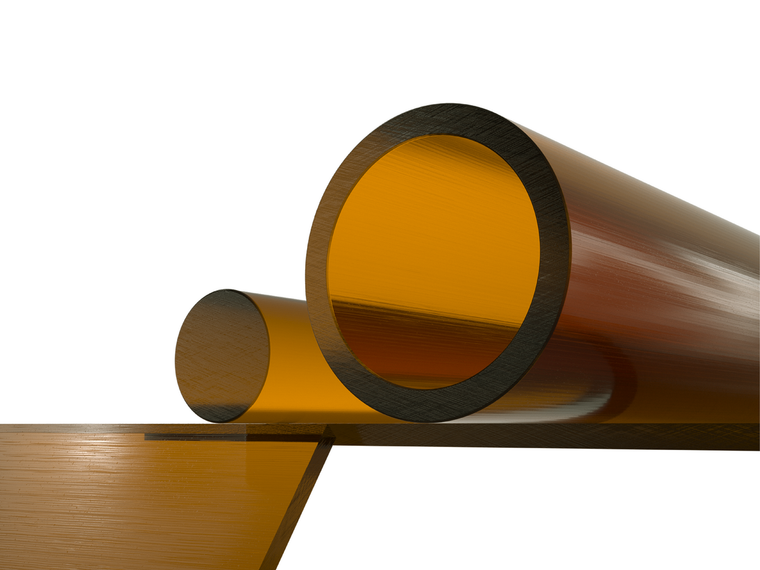

Duratron® PEI U1000 LSG stock shapes are produced from selected batches of a specific Ultem polyetherimide resin. This polymer shows a combination of outstanding mechanical, thermal and electrical properties combined with a good hydrolysis and chemical resistance. The composition of the resin used for the production of the Duratron LSG PEI stock shapes complies with the regulations that apply in the Member States of the European Union (Directive 2002/72/EC, as amended) and in the United States of America (FDA) for plastic materials and articles intended to come into contact with foodstuffs. Duratron LSG PEI stock shapes have also been successfully type tested for their compliance with both United States Pharmacopeia (USP) and ISO 10993-1 guideline requirements for Biocompatibility Testing of Materials, and they come with full traceability from resin to stock shape. These features, added to a very good sterilizability by means of steam, dry heat, ethylene oxide, plasma and gamma irradiation, make Duratron LSG PEI stock shapes very suitable for applications in the medical, pharmaceutical and biotechnology markets.

Advantages of Duratron® PEI U1000 LSG:

- High strength and performs in continuous use to 340°F (170°C)

- High dielectric strength

- Very good sterilizability by means of:

- Steam

- Dry heat

- Ethylene oxide

- Plasma and gamma radiation

- FDA compliant

- ISO 10993-1 compliant

Target industries:

- Medical

- Pharmaceutical

- Biotechnology