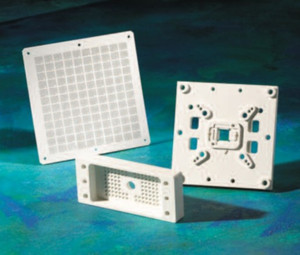

Kyron® GC-100, presented by Port Plastics, redefines the standards for high-temperature, high-stability applications in the semiconductor industry. This injection-molded material is specially designed without fiber toprovide outstanding stiffness and superior machinability, making it an excellent choice for burn-in and test socket applications that demand an extremely high degree of precision and stability. With its unique combination of ultra-stiffness, low coefficient of thermal expansion (CTE), and exceptional dimensional stability, Kyron® GC-100 ensures that your components are produced with unparalleled accuracy.

- ULTRA-STIFF POLYMER: Kyron® GC-100 offers exceptional dimensional stability for semiconductor back-end test applications. Non-fiber filled, ensuring ultra-stiffness for precise component fabrication.

- ENHANCED MACHINABILITY: Designed for superior micro-machinability, enabling highly detailed and accurate machining without the presence of fiber. Ideal for burn-in and test socket applications.

- LOW CTE: Exhibits low coefficient of thermal expansion (CTE), providing stability across a wide range of temperatures and test conditions. Ensures consistent performance in variable environments.

- COST-EFFECTIVE: Injection-molded plates offer a low-cost alternative to polyimides, making high-performance materials more accessible for various projects.

- HIGH ACCURACY: Low tensile elongation allows for increased accuracy in hole placement and component sizing, critical for semiconductor manufacturing.

- THICKER CROSS SECTIONS: Available in 6mm, 9mm, & 12mm thicknesses, complementing Semitron® MDS-100 for applications requiring thicker materials.

- WIDE APPLICATION RANGE: Perfect for semiconductor industry professionals seeking reliable materials for burn-in sockets, test sockets, and other precision components.

Kyron® GC-100 is ideal for engineers, designers, and manufacturers within the semiconductor industry, especially those involved in the production of burn-in sockets, test sockets, and other components requiring high precision, stability, and machinability.

Additionally, its ability to maintain stability over a wide range of temperatures and test conditions, coupled with low tensile elongation for precise hole placement, positions Kyron® GC-100 as a cost-effective yet high-performing alternative to more expensive materials. Whether you are developing components with critical tolerances or seeking a reliable material that can withstand the rigors of semiconductor manufacturing, Kyron® GC-100 delivers the quality and performance you need. Choose Kyron® GC-100 for your next project and experience the benefits of a material designed with the semiconductor industry's needs in mind.