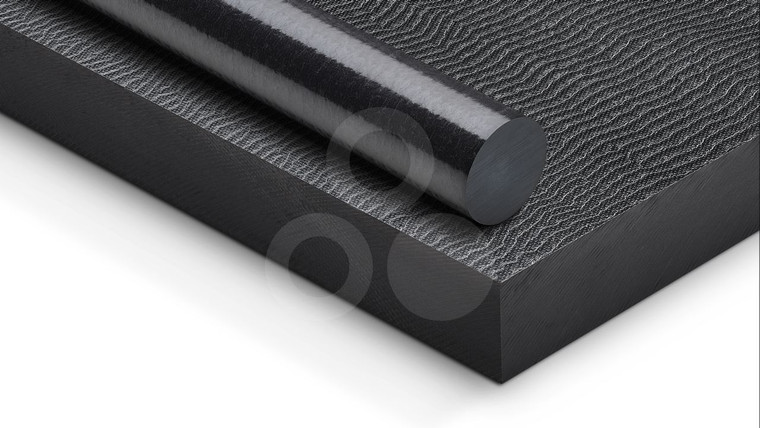

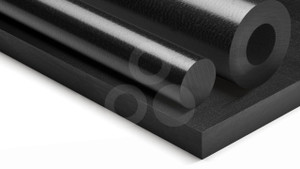

TECAPEEK ® CF30 is a 30% carbon filled PEEK material and its carbon fiber reinforcement lends the material a high level of rigidity and creep strength. Carbon fiber reinforced PEEK demonstrates very high mechanical strength values, while exhibiting lower density than 30% glass fiber filled peek. Furthermore, carbon fiber composites tend to be less abrasive than glass fibers while simultaneously resulting in improved wear and friction properties. The addition of carbon fibers also ensures a significantly higher level of heat conductivity which is also beneficial for increasing part life in sliding applications. Carbon filled PEEK has also an excellent resistance to hydrolysis in boiling water and super-heated steam. Due to its exceptional properties, TECAPEEK CF30 black is utilized in many of the most critical areas in general industry, as well as in the automotive, marine, nuclear, down hole oil well, electronics, and aerospace fields. TECAPEEK CF30 black is also available in a version suitable for medical applications (TECAPEEK MT CF30 black). TECAPEEK® is a registered trademark of Ensinger.

Advantages of TECAPEEK ® CF30 black:

- Very good chemical resistance

- Good heat deflection temperature

- Inherent flame resistance

- Hydrolysis and superheated steam resistant

- Very high stiffness

- Very high creep resistant

- High dimensional stability

- Resistance against high energy radiation

Target industries:

- Aircraft and aerospace technology

- Automotive industry

- Oil and gas industry

- Mechanical engineering

- Chemical plant engineering