UHMW

UHMW Products

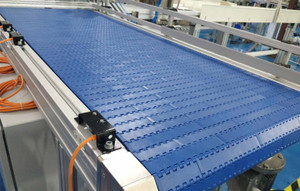

Ultra-High Molecular Weight Polyethylene (UHMW) is a high-performance plastic known for its exceptional durability, low friction, and excellent resistance to wear and abrasion. UHMW is widely appreciated for its impact strength and its ability to withstand harsh environmental conditions, making it a preferred material in a variety of industrial applications, including material handling, food processing, and mining.

Features and Benefits

- Outstanding Durability: Highly resistant to wear, abrasion, and impact.

- Low Friction Surface: Minimizes adhesion and facilitates smooth material flow.

- Chemical Resistance: Stands up to a wide range of chemicals and solvents.

- Low Moisture Absorption: Maintains performance in wet environments.

- Easy to Machine: Can be fabricated into a wide range of shapes and sizes.

Applications

- Conveyor systems and guide rails

- Wear strips and liners

- Marine fender pads

- Food